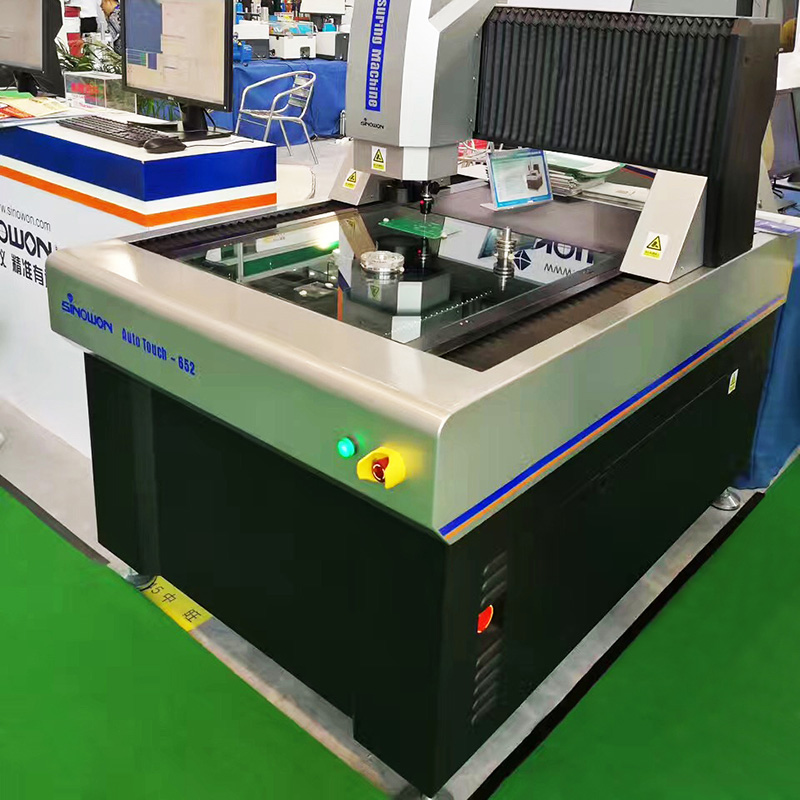

Vision measurement systems are noncontact dimensional inspection machines that combine a camera or multiple cameras with video, lighting and analytical software. They can recognize product shapes, measure and sort parts at high speeds.

A wide variety of industries rely on these automated machines to ensure their work meets internal and industry standards. Here are just a few benefits of using them:

Accuracy

Vision inspection systems are an effective way to control your production process. These machines can detect flaws that are impossible for humans to see, resulting in improved yields and better quality.

They can also locate objects that may be misplaced or positioned incorrectly on your conveyor line, helping you avoid scrap and ensure quality. They can even recognize unique product shapes and measure parts at high speeds.

The accuracy of a machine vision system depends on many factors, including the light source, camera settings, and image processing techniques. To achieve the highest accuracy, a system should be able to compensate for modest translation and rotation errors. It should also be able to trace edges using subpixel processing techniques and not just pixel values. This can reduce the number of pixels that need to be measured, allowing you to increase your system throughput.

Efficiency

Machine vision systems allow you to inspect the quality of products without touching them, saving time and money in the process. These inspections are more precise than manual methods, so they eliminate costly errors and reduce waste. And unlike humans, vision systems don’t need healthcare benefits or 401ks, so they also reduce labor costs.

Using sophisticated algorithms, vision inspection systems can detect and measure small features that are often too small for human eyes. These advancements will improve productivity and enable businesses to perform tasks that would be impossible for humans (e.g., visual-inertial odometry, object recognition with covert data acquisition). As the use of vision inspection technology grows, so does its impact on industry. The future looks bright for manufacturing and business alike.

Safety

Vision systems can locate objects, identify them, and count parts quickly and accurately. This can help your company save time and money by reducing the need to hire additional staff to do these tasks manually.

While human vision is best for qualitative interpretation of a complex, unstructured scene, machine vision excels at quantitative measurement of a structured one. This means that vision-based gauging tools can deliver accurate, repeatable dimensional measurements consistently in production lines where human inspectors are not available.

Vision measurement systems work by using a video camera with a zoom or telecentric lens to detect the edge of a part feature (the difference between light and dark areas). Software can then reconstruct the complete 2D or 3D feature, such as a point, line, or arc on a surface.

Reliability

Reliable vision systems boost product quality, increasing customer satisfaction and brand value. In turn, this can increase revenue and profitability.

Vision inspection systems reduce scrap and waste by eliminating costly human error. They also improve productivity so manufacturers can meet production deadlines.

Vision measurement systems use digital cameras that capture objects and images, then construct the complete image in software pixel line by pixel line. These digital signals are quickly passed to a communication system, which then intervenes on or controls the machine elements. A variety of camera and sensor technologies are available to match a vision application’s performance requirements. These include smart sensors, dumb or video cameras with various lens types, lighting and image-forming systems. A variety of software tools make it easy to set up and monitor a vision system’s functions and parameters.

Productivity

In addition to saving money on labor, vision inspection systems increase productivity by reducing scrap. They also allow for 100% inspection of products so that all parts will meet quality specifications.

Using cameras and sensors to collect data on the surface of a part or product, machine vision systems feed this information to a computer that makes decisions based on what it sees. The system then communicates the decision to specific machine elements, making them intervene as needed in the production process.

This technology is vital in many industrial applications, such as robotic guidance. Light industrial robots equipped with vision systems can dynamically interpret their environment and use this information to make intelligent decisions, such as how to navigate a warehouse space or determine safe working distances from humans.